“A 0.1% error in machine calibration can lead to a 10% loss in productivity.”

This startling statistic from a 2023 industry report underscores a harsh truth: Even the tiniest miscalibration can ripple into massive consequences. Like a single misaligned gear grinding an entire engine to a halt, uncalibrated machines don’t just underperform—destabilize industries where precision is non-negotiable.

Consider the invisible risks lurking in your equipment:

- In manufacturing, a torque wrench missing its calibration by a fraction can compromise entire automotive assembly lines, leading to recalls or safety hazards.

- In healthcare, an ultrasound machine with drifting accuracy might misdiagnose a patient, turning trust in technology into tragedy.

- In construction, uncalibrated welding machines can weaken structural joints, silently threatening skyscrapers and bridges.

This is where GOST Egypt steps in—not just as a service provider, but as a guardian of precision. As a leader in machine calibration services, we deliver tailored solutions that match the exacting demands of industries from pharmaceuticals to aerospace. Our work isn’t about tweaking dials; it’s about ensuring your equipment speaks the universal language of accuracy, down to the last decimal.

At GOST Egypt, we turn “close enough” into “perfectly exact.” Because in a world where machines shape realities—from lifesaving diagnoses to towering infrastructures—calibration isn’t optional. It’s essential.

What is Machine Calibration?

Think of your car’s GPS: If it’s off by even a few meters, you might miss your exit entirely. Machine calibration works the same way—it’s the process of fine-tuning equipment to ensure its measurements, outputs, or performance align exactly with international standards like ISO or ANSI. Without it, machines “guess” instead of “know,” risking errors that snowball into costly inefficiencies.

Calibration vs. Maintenance

Many confuse calibration with maintenance, but they serve distinct roles:

- Maintenance = Keeping equipment functional (e.g., replacing a worn-out part in a welding machine).

- Calibration = Ensuring equipment accuracy (e.g., verifying that the welding machine’s temperature settings match true values).

A piano analogy clarifies this:

- Maintenance is like dusting the piano or fixing a broken key.

- Calibration is tuning every string to the correct pitch so it plays perfect melodies.

Without calibration, even well-maintained machines drift into inaccuracy. For instance, a construction team using an uncalibrated torque wrench calibration machine might apply 10% less force than required, leading to bolts that loosen over time—a silent threat to bridges or machinery.

GOST Egypt’s Precision-Driven Approach

At GOST Egypt, we bridge the gap between “functional” and “flawless.” Our machine calibration services use advanced tools like torque wrench calibration machines and laser-guided systems to validate equipment against global benchmarks. Whether it’s a hospital’s ultrasound machine needing micron-level accuracy or a factory’s hydraulic press requiring exact pressure settings, we don’t just check boxes—we eliminate doubts.

Key Takeaway: Calibration isn’t a “nice-to-have”—it’s how industries speak the language of reliability. And with GOST Egypt, that language is perfect.

The Hidden Costs of Skipping Calibration

“43% of equipment failures trace back to improper calibration.”

This figure from a 2023 industrial safety report isn’t just a number—it’s a wake-up call. Skipping calibration might save time upfront, but the long-term consequences ripple across safety, compliance, and your bottom line. Here’s what’s at stake:

The Domino Effect of Poor Calibration

- Safety Risks That Lurk in Shadows

A welding machine calibration error as small as 2% can weaken joints in pipelines or bridges, creating invisible flaws that escalate into collapses or leaks. In 2022, a European automotive plant recalled 15,000 vehicles due to improperly calibrated torque tools—a mistake costing millions in repairs and reputational damage. - Regulatory Fines & Legal Headaches

Laboratories using uncalibrated equipment risk more than inaccurate results. For example, a pharmaceutical company with non-compliant lab equipment calibration could face FDA fines up to $500,000 for violating Good Manufacturing Practices (GMP). - Wasted Resources: The Silent Profit Killer

Uncalibrated machines consume excess energy, misfire materials, and produce defective batches. A textile factory in Egypt reduced fabric waste by 30% after optimizing their cutting machines through regular calibration—proving precision pays.

How GOST Egypt Shields Your Operations

At GOST Egypt, we don’t just fix problems—we prevent them. Our machine calibration services act as an insurance policy against hidden costs:

- Safety Assurance: Using traceable standards, we ensure your welding machines and UT equipment meet ISO 17638 and ASNT CP-189 benchmarks, eliminating structural risks.

- Compliance Confidence: With ISO/IEC 17025-accredited protocols, your lab equipment calibration stays audit-ready, avoiding fines.

- Resource Optimization: Calibrated machines reduce energy waste by up to 15% (as seen in a 2023 client case study), turning accuracy into ROI.

Key Takeaway: Calibration isn’t an expense—it’s an investment that protects lives, compliance, and profits. GOST Egypt turns “what-ifs” into “never-agains.”

Which Machines Need Calibration? (Beyond the Obvious)

Most businesses know to calibrate their scales or thermometers—but what about the machines hiding in plain sight, quietly shaping outcomes you’d never suspect? From hospital corridors to oil rigs, here’s where calibration becomes a silent hero:

Overlooked Machines That Demand Precision

- Healthcare: Ultrasound Machine Calibration

Imagine a doctor misdiagnosing a pregnancy due to a 5% drift in an ultrasound’s imaging depth. Ultrasound machine calibration ensures these devices don’t just “see” but see accurately, safeguarding patient trust and diagnostic outcomes. - Oil & Gas: UT Machine Calibration

Ultrasonic Testing (UT) equipment inspects pipelines for cracks. But if the machine itself is uncalibrated? It’s like using a broken metal detector to find a needle in a haystack. UT machine calibration ensures flaws aren’t missed, preventing leaks that could trigger environmental disasters. - Construction: Welding Machines

A skyscraper’s stability hinges on welded joints. ISO 17638-compliant welding machine calibration guarantees each weld delivers the exact heat and pressure needed—because “strong enough” isn’t an option when lives are on the line.

Pro Tip: GOST Egypt’s Industry Reach

While these examples grab headlines, calibration matters in every sector. We serve:

- Manufacturing: Presses, CNC machines, and robotic arms.

- Labs: pH meters, spectrometers, and autoclaves.

- Automotive: Torque tools, emission testers, and assembly robots.

- Aerospace: Pressure sensors and navigation systems.

The ROI of Regular Calibration

Think of calibration as a “fitness tracker” for your machines—it doesn’t just check their health; it enhances it. While compliance keeps you in the race, regular machine calibration propels you ahead. Here’s how:

The Tangible Payoff of Precision

- 20% Longer Equipment Lifespan

Calibration reduces wear and tear caused by inefficiencies. For example, a hydraulic press operating at optimal pressure avoids overheating, extending its life by years. A 2022 study by the Global Calibration Institute found that calibrated CNC machines in factories lasted 20% longer than uncalibrated ones. - Zero Recalls, Zero Embarrassment

In manufacturing, a single recall can cost millions. Take automotive giants: Proper welding machine calibration ensures every chassis weld meets exact specs, slashing recall risks. One client in the auto sector reduced warranty claims by 35% after adopting GOST’s calibration schedule. - 15% Energy Savings

Uncalibrated machines overcompensate—like a gas stove burning hotter to hit a target temperature. Calibration fine-tunes energy use. A textile mill in Alexandria cut power bills by 15% after optimizing their looms through GOST’s lab equipment calibration services.

The GOST Advantage: Partnerships That Matter

Our collaborations with global bodies like ISO, ANSI, and DAkkS aren’t just badges—they’re proof that our machine calibration services meet the world’s strictest benchmarks. For instance:

- Aerospace clients benefit from our NADCAP-accredited calibration for mission-critical sensors.

- Pharma labs leverage our FDA-aligned protocols for audit-ready lab equipment calibration.

Key Takeaway: Calibration isn’t a cost—it’s a profit multiplier. With GOST Egypt, you’re not just avoiding fines; you’re unlocking efficiency, sustainability, and a reputation for reliability that money can’t buy.

Where Can I Find Reliable Welding Machine Calibration Near Me?

When your welding machine starts drifting, time isn’t a luxury—it’s a liability. Searching for “welding machine calibration near me” isn’t just about convenience; it’s about urgency. At GOST Egypt, we’ve built a nationwide network to ensure precision is always within reach, whether you’re in Cairo’s industrial zones or a remote oil field in the Western Desert.

Why GOST Egypt is Everywhere You Need Us

- Nationwide Coverage: From Alexandria’s shipyards to Aswan’s solar farms, our technicians are stationed across Egypt. No need to ship equipment or wait weeks—we come to you.

- Mobile Calibration Units: Think of us as the “fire brigade” of calibration. Our fully equipped mobile labs handle on-site welding machine calibration, torque tool checks, and more, minimizing downtime.

- Fast Turnaround, Zero Compromise: Need ISO 17638-compliant calibration within 48 hours? We’ve done it for auto parts manufacturers on the 6th of October City and steel plants in Suez.

The GOST Difference: Local Expertise, Global Standards

While others outsource or cut corners, our mobile teams bring the same certified precision as our main labs. For example:

- A Hurghada construction firm avoided a 2-week project delay with our 24-hour welding machine calibration service.

- A Luxor agricultural equipment manufacturer slashed maintenance costs by 25% through our scheduled on-site visits.

Your machines shouldn’t wait—and neither should you.

Key Takeaway: With GOST Egypt, “near me” isn’t a search—it’s a guarantee. Fast, local, and uncompromisingly precise, we’re redefining what it means to deliver machine calibration services where they matter most.

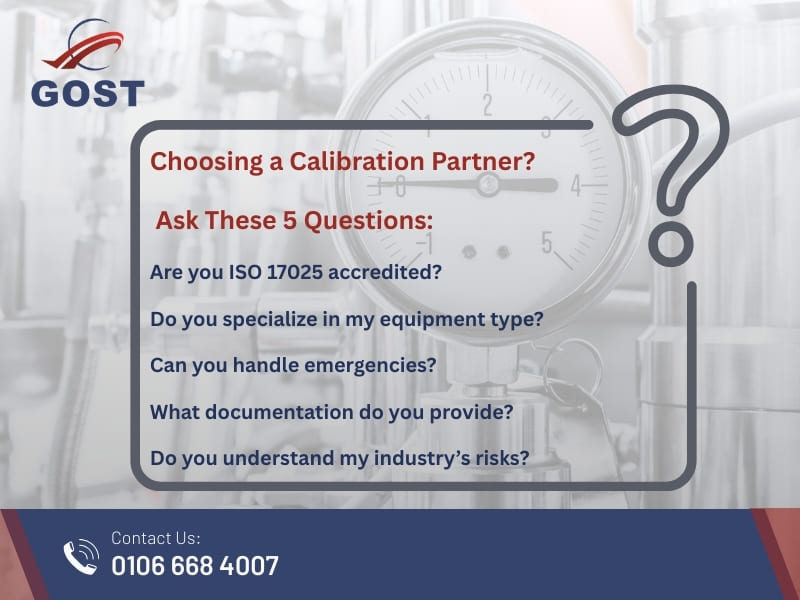

Choosing a Calibration Partner

Selecting a calibration lab isn’t just about ticking boxes—it’s about finding a partner who treats precision as a non-negotiable. Before entrusting your equipment, ask these critical questions:

1. “Are You ISO 17025 Accredited?”

This certification isn’t just paperwork—it’s proof a provider meets global competence standards. For example, ISO 17025 ensures technicians use traceable calibration methods, critical for industries like aerospace or pharmaceuticals. (GOST Egypt is ISO 17025 accredited, but we’ll let our work speak for itself.)

2. “Do You Specialize in My Equipment Type?”

A generalist might mishandle niche tools. If you rely on UT machine calibration for pipeline inspections or ultrasound machine calibration for medical diagnostics, choose a partner with proven expertise in your field.

3. “Can You Handle Emergencies?”

Machines don’t fail at convenient times. A provider offering 24/7 emergency services can save you from costly downtime—like recalibrating a welding machine mid-project to avoid construction delays.

4. “What Documentation Do You Provide?”

Robust records are your shield during audits. Ensure they supply:

- Certificates traceable to international standards.

- Detailed reports on pre- and post-calibration performance.

- Compliance evidence for regulations like ISO 9001 or FDA 21 CFR.

5. “Do You Understand My Industry’s Risks?”

A food processing plant’s thermometer calibration needs differ wildly from an oil refinery’s UT machine calibration. Your provider should grasp your unique stakes—whether it’s preventing contamination or avoiding refinery leaks.

Why These Questions Matter

Calibration isn’t a transaction; it’s a relationship. The right partner doesn’t just fix machines—they anticipate risks, align with your industry’s heartbeat, and turn precision into your silent advantage.

In a world where machines power progress, calibration is the unsung hero ensuring safety, efficiency, and trust. From preventing structural disasters with welding machine calibration to safeguarding patient lives through ultrasound machine calibration, precision isn’t optional—it’s the backbone of every industry.

At GOST Egypt, we don’t just calibrate equipment; we build confidence. Whether you’re a factory manager in Alexandria or a lab technician in Cairo, our machine calibration services turn uncertainty into unwavering accuracy.

Your machines deserve precision. Contact GOST Egypt today for a free consultation—because “good enough” is never enough.

FAQ about Machine Calibration

How often should I calibrate my ultrasound machine?

Annual calibration is recommended, but high-usage environments may need quarterly checks. GOST Egypt offers automated reminders to keep your schedule stress-free.

What’s the cost of torque wrench calibration?

Costs vary based on usage and complexity, but our plans start at affordable rates. For example, monthly industrial use may cost less than you’d spend on post-calibration repairs.

Can you calibrate equipment on-site?

Absolutely! Our mobile units handle UT machine calibration, welding tools, and more nationwide, minimizing downtime.

Do you provide certificates for audits?

Yes. Every service includes ISO-compliant documentation, ensuring you’re always audit-ready.

Contact GOST Egypt

Head Office

- Address: 122 Galal El Desouki Street, Wabor Elmyah, Bab Sharki, Royal Palace Tower, Alexandria, Egypt

- Email: info@gostegypt.com

- Phone: +2 03 4228 204 – 4228 234

- Mobile: +2 0106 668 4007

- Fax: +2 03 4228 234

Cairo Office

- Address: 8 El Sudan Street, El Dokki, Cairo, Egypt

- Email: cairo@gostegypt.com

- Phone: +2 02 3760 6450

- Mobile: +2 0109 002 6744

Fax: +2 02 3760 6450