Every time you step into an elevator or trust a medical device, you’re relying on the silent precision of mechanical calibration—a process so critical, yet often invisible. It’s what ensures that the machines shaping our modern world, from factory robots to life-saving hospital equipment, perform exactly as they should.

Put simply, mechanical calibration is the science of fine-tuning tools and instruments to meet strict accuracy standards. Like a musician tuning their guitar before a concert, calibration aligns equipment with universal benchmarks, eliminating errors before they escalate into costly—or even dangerous—mistakes.

At GOST Egypt, we specialize in this unsung hero of industry. Our team ensures that the devices you depend on daily—whether in laboratories, production lines, or energy plants—operate with flawless precision. Because when machinery falls out of sync, the ripple effects can be far-reaching: delayed projects, compromised safety, and eroded trust.

Mechanical calibration isn’t just a technical checkbox. It’s the backbone of progress in a world where “close enough” is never enough. Let’s explore why this discipline matters now more than ever—and how GOST Egypt delivers the exactness industries need to thrive.

The Risks of Neglecting Mechanical Calibration

Behind every smoothly operating machine is a silent guardian: mechanical calibration. Ignore it, and the consequences ripple far beyond a simple misaligned gauge. According to the National Institute of Standards and Technology (NIST), 30% of equipment failures in industrial settings stem from improper calibration—a startling reminder that precision isn’t optional.

What Happens When Calibration Is Overlooked?

- Safety Hazards: Uncalibrated pressure valves in HVAC systems can overheat, while misaligned torque tools in automotive assembly lines may loosen critical bolts. The result? Equipment malfunctions that endanger workers and end-users alike.

- Financial Losses: Inaccurate measurements from poorly calibrated sensors can derail production timelines. For example, a food packaging plant relying on uncalibrated fill-level detectors might waste tons of raw materials—or face costly recalls.

- Compliance Violations: Regulated industries like pharmaceuticals operate under strict guidelines. A single deviation caused by uncalibrated lab instruments could lead to fines, halted operations, or even revoked certifications.

Why “Good Enough” Isn’t Enough

Consider a pharmaceutical company using a mechanical calibration service to validate its tablet-weighing scales. Without this step, a tiny measurement drift could mean tablets contain 10% less active ingredient—a flaw undetectable to the eye but catastrophic for patient health and regulatory compliance.

This is where GOST Egypt’s mechanical instrument calibration expertise becomes indispensable. By identifying and correcting minor deviations early, we help businesses avoid risks that snowball into crises. Because in precision-driven industries, there’s no room for “almost right.”

GOST Egypt’s Approach

At GOST Egypt, mechanical calibration isn’t just a service—it’s a synergy of cutting-edge technology, rigorous standards, and human expertise. As a leader in the field, we’ve built our reputation on three pillars:

- Certified Precision: Our state-of-the-art labs are accredited to ISO 17025, the gold standard for testing and calibration laboratories. This means every adjustment, measurement, and report meets globally recognized benchmarks for accuracy and repeatability.

- Advanced Tools for Micro-Level Accuracy:

- Torque testers that validate machinery down to 0.1% uncertainty.

- Digital pressure gauges capable of detecting deviations as subtle as 0.01 psi.

- Laser alignment systems that ensure industrial equipment operates with near-perfect geometry.

- Skilled Technicians: Our team isn’t just trained—they’re specialists with decades of collective experience in sectors like aerospace, healthcare, and energy. They don’t just follow protocols; they anticipate challenges unique to your equipment.

What sets GOST Egypt apart is how these elements intersect. Our Mechanical Calibration Lab functions like a surgical theater: controlled environments eliminate external variables, traceable reference standards act as our “true north,” and technicians work with the focus of master watchmakers.

Whether it’s a pharmaceutical clean room requiring nanoscale precision or a manufacturing plant needing rapid on-site calibration, GOST Egypt turns complexity into clarity. Because when machinery aligns with perfection, so does your success.

Industries That Rely on Mechanical Calibration Services

From hospitals to oil fields, industries thrive on machinery that performs flawlessly—and mechanical calibration is the invisible thread tying this reliability together. Here’s how three sectors depend on precision to function:

1. Healthcare: Where Millimeters Matter

- MRI Machines: A misaligned MRI scanner could blur tumor boundaries, delaying diagnoses. Calibration ensures magnetic fields and imaging sensors operate within exact tolerances.

- Surgical Tools: Robotic arms used in minimally invasive surgeries require micron-level accuracy. Even a 0.1mm drift could turn a routine procedure into a life-threatening error.

GOST Egypt’s Role: We provide mechanical calibration in laboratory settings for medical devices, adhering to ISO 13485 standards to meet healthcare’s zero-error demands.

2. Manufacturing: The Heartbeat of Production

- Assembly Line Robots: A robotic welder in an automotive plant must repeat movements within ±0.02mm. Uncalibrated robots risk misaligned parts, leading to recalls or safety issues.

- Packaging Systems: Fillers, sealers, and labelers rely on synchronized sensors. A 1% deviation in a bottling line could waste thousands of liters of product daily.

GOST Egypt’s Role: Our mobile calibration units perform on-site adjustments, minimizing downtime while keeping production lines compliant and efficient.

3. Energy: Powering Progress Safely

- Pipeline Pressure Sensors: Undetected pressure spikes in oil and gas pipelines can trigger leaks or explosions. Calibration ensures sensors detect changes as small as 0.5% of full scale.

- Wind Turbines: Misaligned torque in turbine gearboxes accelerates wear, reducing lifespan by years. Regular calibration optimizes performance and prevents catastrophic failures.

GOST Egypt’s Role: We deploy ruggedized equipment and technicians trained for harsh environments, ensuring calibration withstands desert heat or offshore humidity.

Tailored Solutions for Unique Challenges

Whether calibrating a lab microscope for pharmaceutical research or a hydraulic press in aerospace manufacturing, GOST Egypt customizes its approach. Our mechanical calibration services adapt to your industry’s pace, precision needs, and regulatory landscape—because a one-size-fits-all solution doesn’t exist in a world built on exactness.

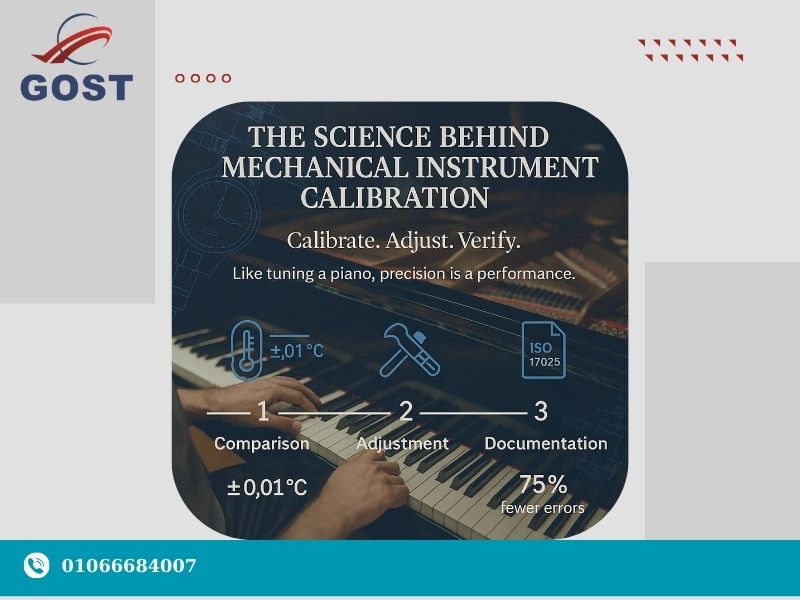

The Science Behind Mechanical Instrument Calibration

Think of mechanical calibration as tuning a grand piano. Just as each string must vibrate at an exact frequency to produce the perfect note, every instrument—whether a torque wrench or a pressure sensor—must align precisely with universal standards. The process isn’t magic; it’s methodical science. Here’s how it works:

The Three-Step Symphony of Calibration

- Comparison: Instruments are tested against reference standards traceable to national or international bodies (like NIST or ISO). For example, a factory’s thermometer might be compared to a lab-grade standard accurate to ±0.01°C.

- Adjustment: If deviations are found, technicians tweak the device—like tightening a piano string—until its readings match the reference.

- Documentation: Every test and adjustment is recorded in a calibration certificate, a “passport” proving the device meets required specs.

A 2022 study in Measurement Science Review underscores why this rigor matters: calibrated devices reduce error margins by 75% compared to unchecked equipment. That’s the difference between a surgeon’s scalpel landing precisely and missing its mark.

Why GOST Egypt Masters This Science

Our mechanical calibration process combines cutting-edge tools with meticulous protocols. For instance, calibrating a pressure gauge involves simulating real-world conditions (extreme temperatures, vibrations) to ensure it performs flawlessly after leaving the lab. It’s not just about hitting a number—it’s about guaranteeing reliability in the chaos of daily use.

Like a perfectly tuned piano, a calibrated instrument doesn’t just function—it performs. And GOST Egypt ensures your equipment hits every note, every time.

The Unexpected Benefits of Regular Calibration

While mechanical calibration is often seen as a regulatory hurdle, its true value lies in the hidden dividends it pays long after the process is complete. Think of it as a “health check-up” for machinery—preventative care that unlocks three powerful advantages:

- Extended Equipment Lifespan: Misaligned parts strain machinery, accelerating wear. Regular calibration corrects minor deviations early, helping tools last 20–30% longer.

- Reduced Downtime: Calibrated equipment breaks down less often. A study by Plant Engineering found facilities with scheduled calibration cut unplanned downtime by up to 45%.

- Enhanced Brand Reputation: Precision builds trust. A food manufacturer using calibrated filling machines, for instance, avoids underfilled packages that erode consumer confidence.

Take the case of a Cairo-based automotive parts factory. After partnering with GOST Egypt for routine mechanical calibration, they slashed annual maintenance costs by 40% and reduced production halts caused by faulty machinery. “We stopped seeing calibration as an expense,” their lead engineer noted. “It became an investment in predictability.”

At GOST, we believe calibration shouldn’t just meet standards—it should exceed expectations. By turning precision into a competitive edge, we help businesses not only comply but thrive.

FAQs About Mechanical Calibration Services

Got questions? We’ve got straightforward answers. Here’s what clients often ask about mechanical calibration services:

How often should equipment be calibrated?

It depends on three factors:

- Industry requirements: Pharmaceuticals might need monthly checks; manufacturing tools may require quarterly calibration.

- Usage frequency: A torque wrench used daily needs more frequent calibration than one used weekly.

- Environmental stress: Equipment exposed to heat, vibration, or dust may drift faster.

GOST Egypt’s Tip: We analyze your equipment’s role and risks to create a tailored schedule—no guesswork needed.

Can GOST handle on-site calibration?

Absolutely! Our mobile labs and portable calibration kits bring precision to your doorstep. For example:

- Manufacturing plants: Calibrate assembly line robots without halting production.

- Hospitals: Validate MRI machines in controlled environments to avoid patient disruptions.

On-site or in-lab, GOST ensures the same ISO-compliant results.

How do you calibrate a mechanical machine?

In three simplified steps:

- Test: Compare the machine’s output against a certified reference standard.

- Adjust: Fine-tune components (e.g., sensors, gears) to eliminate deviations.

- Verify: Re-test to confirm alignment with required tolerances.

Think of it like tuning a guitar: even a slightly off string ruins the harmony.

What is machine calibration?

Calibration is the process of ensuring a machine’s measurements or outputs match trusted standards. For instance, a scale showing 100 grams must actually measure 100 grams—not 99 or 101. Without this step, “accuracy” is just a guess.

Why GOST Stands Out

Our mechanical instrument calibration isn’t a checkbox exercise. We combine rigor with practicality, whether calibrating a lab microscope or a construction crane. Have more questions?

In a world where machinery drives progress, mechanical calibration is the silent guardian of safety, efficiency, and trust. It’s not just about adjusting tools—it’s about safeguarding lives, protecting investments, and ensuring industries move forward without compromise.

At GOST Egypt for Calibration Services, we believe precision is a partnership. From our ISO-certified labs to your facility floor, we’re committed to delivering accuracy that lasts.

Ready to optimize your equipment? Let GOST Egypt be your precision partner.

Contact Us Today

Head Office

- Address: 122 Galal El Desouki Street, Wabor Elmyah, Bab Sharki, Royal Palace Tower, Alexandria, Egypt

- Email: info@gostegypt.com

- Phone: +2 03 4228 204 – 4228 234

- Mobile: +2 0106 668 4007

- Fax: +2 03 4228 234

Cairo Office

- Address: 8 El Sudan Street, El Dokki, Cairo, Egypt

- Email: cairo@gostegypt.com

- Phone: +2 02 3760 6450

- Mobile: +2 0109 002 6744

- Fax: +2 02 3760 6450