Pressure vessel inspection failures have been linked to some of the most catastrophic industrial accidents in history — from chemical plant explosions to severe injuries and costly shutdowns. According to a global safety study published by the U.S. Chemical Safety Board, nearly 40% of pressure-related incidents occurred due to lack of regular inspection or improper testing. That’s not just a technical oversight — it’s a safety risk with real consequences.

A pressure vessel, in its simplest form, is a sealed tank designed to hold pressurized gases or liquids. While they may look like just another part of the system, these vessels bear extreme internal forces that require strict monitoring. Without timely inspection, corrosion, weld failures, or unseen pressure buildup can turn a quiet machine into a high-risk hazard.

This is where GOST Egypt steps in. As a trusted name in industrial inspection, we deliver certified, highly precise inspection services that help prevent failures before they start. With every check we perform, we don’t just look at a vessel — we look after the lives and operations that depend on it.

Why Pressure Vessel Inspection is Non-Negotiable

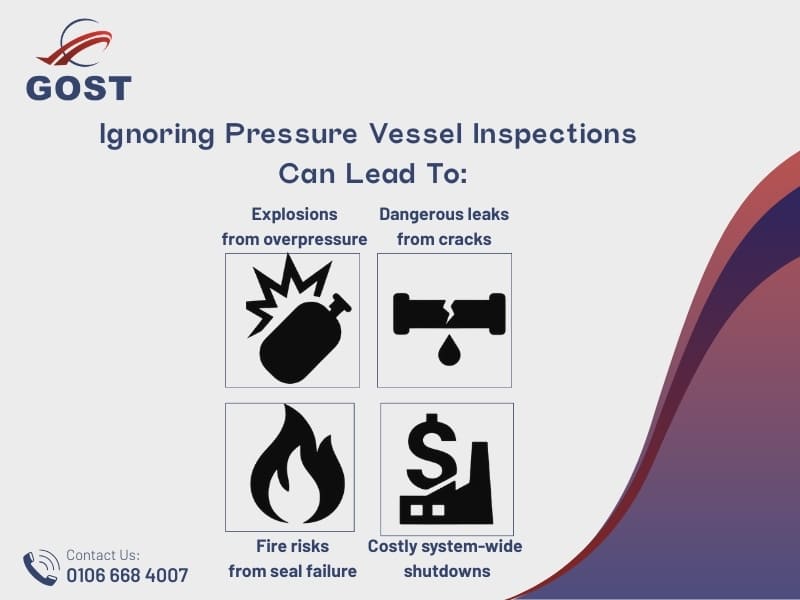

Ignoring pressure vessel inspection is not just risky — it’s dangerous. Industrial records show that equipment operating under pressure, if left unchecked, has caused:

- Sudden explosions due to internal overpressure

- Hazardous gas or fluid leaks from undetected cracks

- Fire hazards from seal failures

- Long-term structural damage to nearby systems

These failures don’t just affect machinery. They injure people, damage property, and in many cases, result in costly shutdowns that companies could have easily avoided with routine pressure inspection.

Legal and Regulatory Requirements You Must Follow

In Egypt, pressure systems fall under the scope of national safety and labor codes. These laws require companies to perform documented inspections at specified intervals, using certified professionals and approved testing methods. Failing to meet these standards may result in:

- Heavy penalties or forced shutdowns

- Withdrawal of operational licenses

- Legal liability in case of workplace accidents

Globally

International regulations, such as those from ASME, API, and ISO, outline strict criteria for pressure vessel inspection companies to follow. These standards govern everything from how often vessels should be tested to the exact inspection procedures used.

Inspections Protect Workers and Preserve Operations

A reliable pressure tank inspection routine is one of the most powerful tools to safeguard worker lives and operational efficiency. Here’s how:

- Early Detection: Inspections catch corrosion, weld fatigue, or pressure anomalies before they become serious.

- Worker Safety: By identifying potential rupture risks, inspections reduce the chances of injury or fatal accidents.

- Less Downtime: Preventative testing ensures fewer emergency breakdowns, keeping production on schedule.

- Insurance Compliance: Certified inspection reports are often required for industrial insurance coverage.

At GOST Egypt, our inspection protocols are aligned with both local and international standards, ensuring that your equipment remains fully compliant and audit-ready at all times.

When and How Often Should You Perform Inspections?

How often should you conduct pressure vessel inspection? The answer isn’t one-size-fits-all. Inspection intervals vary based on the vessel’s application, material, operating pressure, and exposure to corrosive elements. However, there are standard checkpoints every responsible facility must follow:

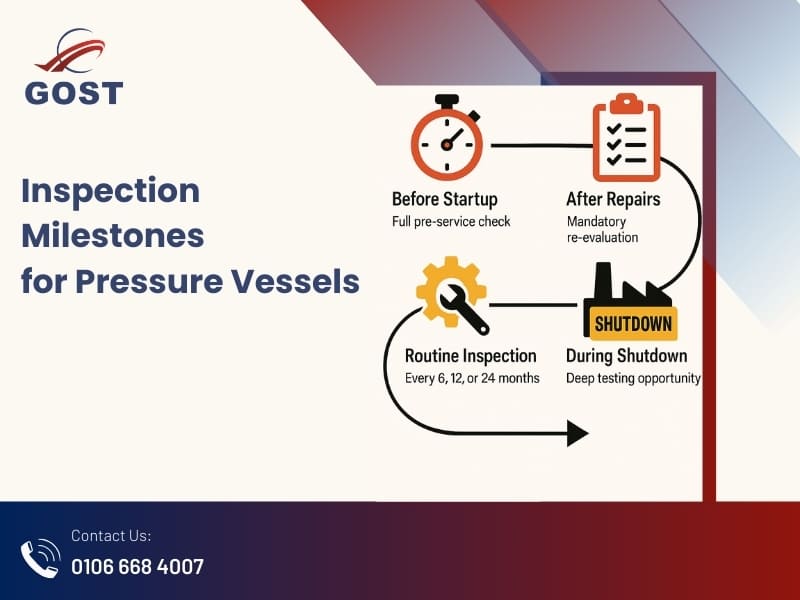

Key Inspection Milestones

- Before Startup: Every newly installed vessel should undergo a full inspection and documentation before entering service.

- Periodically During Operation: Depending on the industry and pressure class, inspections may be required every 6, 12, or 24 months.

- Post-Repair or Modification: If the vessel has undergone repairs or design changes, it must be re-evaluated for structural integrity.

- During Shutdown: Scheduled plant shutdowns are ideal opportunities for in-depth testing, cleaning, and documentation.

Types of Inspection

Pressure Vessel Inspection is more than just a visual walkthrough. Each method plays a role in ensuring the vessel’s long-term reliability and safety.

Common Inspection Types:

- Visual Examination (VT)

A surface-level check for signs of rust, leakage, or deformation. Often done during routine maintenance. - Pressure Vessel NDT Inspection

Uses advanced tools like ultrasonic testing, magnetic particle testing, or radiographic scans to detect internal flaws without damaging the equipment. - Hydrostatic Testing

The vessel is filled with water and pressurized beyond normal levels to confirm it can withstand operating stress. - Full Certification Tests

These involve a complete review of performance data, prior test reports, and structural analysis, often required by third-party agencies for licensing or export.

High-Risk Industries Need Stricter Schedules

Some industries demand more aggressive Pressure Vessel Inspection timelines due to safety sensitivity, product contamination risks, or extreme operating environments.

Examples of Industries with Tight Schedules:

- Oil & Gas: Due to high temperatures and flammable contents, pressure systems inspections are performed every 6–12 months.

- Food Processing: Frequent pressure vessel testing is needed to ensure hygienic, contaminant-free operations.

Pharmaceuticals: Regulatory agencies mandate detailed documentation and frequent audits. - Chemical Plants: Corrosive materials and high operating pressures demand continuous monitoring and scheduled pressure inspection.

Types of Pressure Vessel Inspections We Offer at GOST Egypt

At GOST Egypt, we provide a full range of certified inspection services tailored to your industry’s unique needs — whether you’re managing a high-pressure steam system or a small process tank. Our inspections are conducted in strict alignment with international codes, ensuring both safety and regulatory compliance.

Our Comprehensive Inspection Services Include:

- Visual Inspection

The first line of defense. We perform detailed visual evaluations to detect surface flaws, weld issues, corrosion, and structural deformations. This is a required step in boiler pressure vessel inspection and other regulated systems. - Ultrasonic Testing (UT)

A key NDT test for pressure vessel integrity. UT detects internal cracks, thinning walls, and hidden corrosion without opening or damaging the vessel — ideal for high-value or pressurized systems. - Magnetic Particle Testing (MT)

This method pinpoints surface and near-surface flaws in ferromagnetic materials. Often used alongside visual checks to assess welds and joints in critical pressure zones. - Radiographic Testing (RT)

A powerful imaging method using X-rays or gamma rays to expose internal defects. Pressure vessel testing companies typically recommend RT for evaluating welds and hidden stress points in high-risk environments. - Leak Testing & Hydrostatic Testing

We perform standard pressure vessel testing and hydrostatic pressure tests by filling the vessel with water and applying pressure beyond its operational threshold. This confirms structural integrity under stress and is essential before system reactivation. - Final Documentation & Compliance Reports

After all inspections are complete, we compile a detailed report including test results, photographic records, and compliance checklists. This documentation meets Egyptian standards and international codes — critical when working with global partners or regulatory audits.

Factory Acceptance Test (FAT) and Its Role in Pressure Systems

While many clients ask about the Factory Acceptance Test (FAT) when discussing pressure vessel inspection, it’s crucial to clarify a key distinction: FAT is primarily used for mechanical and electrical systems, not for fixed equipment like pressure vessels, boilers, or heat exchangers.

At GOST Egypt, our role is not just to inspect but to educate. We help clients understand that applying FAT to pressure vessels is technically incorrect — and that’s the kind of precision that sets top pressure vessel inspection companies apart from general providers.

Where FAT Is Relevant

Although FAT isn’t applied to pressure vessels, it plays a significant role in systems that often work alongside or within pressurized environments:

- Pumps: FAT involves performance, mechanical, and vibration tests to ensure compliance with the purchase specification before shipping.

- Compressors: Mechanical running and dynamic balancing tests confirm readiness before integration into high-stress pressure systems.

- Turbines and Induction Motors: FAT verifies temperature rise limits, speed control, and operational endurance — all vital when connected to pressure-based operations.

Why This Matters to Your Inspection Plan

When clients manage complex infrastructures, it’s common to confuse test requirements across system types. That’s where GOST Egypt’s technical depth becomes valuable. We help you navigate these distinctions to avoid wasted time and ensure every component — whether fixed or rotating — is inspected under the correct standard.

So while FAT won’t apply directly to a pressure vessel inspection, it remains a critical part of broader pressure systems inspections, especially when assessing the components that support, drive, or regulate pressure-related equipment.

Documentation & Compliance Support from GOST Egypt

In any pressure vessel inspection, a clean test result isn’t enough. What truly confirms safety, compliance, and operational readiness is the supporting documentation — reports that trace every test, note every observation, and align with industry-recognized standards like ASME, API, and local Egyptian regulations.

Without complete and organized documentation, even a well-tested vessel can face legal issues, insurance claims, or shutdowns during audits.

What GOST Egypt Provides

At GOST Egypt, we go beyond standard checklists. Our engineers and certified inspectors deliver:

- Full inspection reports with traceable records

- Step-by-step breakdowns of tests performed, including pressure tank testing and material validations

- Cross-referenced documentation with the project’s original ITP (Inspection & Test Plan)

- Final approval from third-party inspectors, where required

- All data aligned with the latest editions of applicable codes and standards

Built for Transparency and Compliance

Every document we deliver is written with both technical teams and regulators in mind. That means clarity, accuracy, and full traceability from the first weld to the last pressure hold test. For clients managing audits, certifications, or export shipments, this level of support is essential.

We know that in regulated sectors like oil & gas, food processing, and pharmaceuticals, incomplete documentation is as risky as a faulty vessel. That’s why GOST Egypt ensures every detail is reviewed, certified, and ready for compliance — making us one of the most reliable pressure vessel testing companies in the region.

Why Choose GOST Egypt for Pressure Vessel Inspection?

When it comes to pressure vessel inspection, choosing the right partner is essential for minimizing risk and ensuring the safety of your operations. At GOST Egypt, we are committed to precision and excellence. Our team of certified inspectors possesses the deep technical know-how and experience necessary to perform thorough, reliable inspections.

We are fully certified to meet industry standards, including ASME, API, and local regulatory codes. Our understanding of the nuances of pressure systems inspections is unmatched, allowing us to offer a level of expertise that sets us apart from many other pressure vessel inspection companies in Egypt.

Comprehensive Inspection Services Across Egypt and Beyond

GOST Egypt extends its high-quality pressure vessel testing services not only throughout Egypt but also to neighboring markets. Our extensive inspection scope covers critical sectors such as oil & gas, manufacturing, food processing, and more — helping companies meet both local and international standards.

Real-World Benefits for Your Business

Choosing GOST Egypt means choosing to minimize operational risks. Here’s how we make a difference:

- Minimized Risk: Our pressure tank inspection services ensure that every vessel is assessed for structural integrity, preventing potential failures that could lead to costly downtime or accidents.

- Compliance Assurance: We help ensure your equipment meets regulatory and safety standards, avoiding penalties and keeping your business in compliance with national and international laws.

- Audit Readiness: GOST Egypt’s comprehensive reports, certified by experts, prepare your equipment for audits, making your life easier when dealing with inspections from external bodies.

With GOST Egypt, you can trust that your pressure vessel inspection is in expert hands. We provide unparalleled reliability, transparency, and expertise in every inspection we perform.

Ready to Inspect Pressure?

Don’t leave the safety and compliance of your pressure systems to chance. Contact GOST Egypt today to schedule your next pressure vessel inspection and ensure the ongoing safety of your operations.

Our expert team is ready to assist you with:

- Quick Response: Reach out to us anytime, and our team will promptly address your needs.

- Flexible Scheduling: We work around your schedule to ensure minimal disruption to your operations.

- Field-Proven Expertise: With years of industry experience, we are trusted by businesses across Egypt and beyond.

FAQs about

How Often Does a Pressure Vessel Need to Be Inspected?

The frequency of pressure vessel inspection depends on factors such as the vessel’s service conditions, operating environment, and the type of fluids being stored or processed. Generally, inspections should be conducted:

- Annually: For most operational vessels, a yearly inspection is standard.

- Post-repair or modification: After repairs or changes to the vessel, a thorough inspection is required before it is put back into service.

- Shutdown: When vessels are shut down for maintenance, a comprehensive inspection should be done to ensure everything is in order.

Industries like oil & gas and food processing may require more frequent inspections to comply with stringent safety standards.

What is the ASME for Pressure Vessel Testing?

The ASME (American Society of Mechanical Engineers) sets the ASME Boiler and Pressure Vessel Code (BPVC), which outlines the standards for the design, construction, and inspection of pressure vessels. These guidelines help ensure that pressure vessels are constructed and maintained to the highest safety standards. During pressure vessel testing, compliance with ASME codes is essential for ensuring that the vessel operates safely under pressure and meets the required certifications.

What is API RP 572 Inspection of Pressure Vessels?

API RP 572 (American Petroleum Institute Recommended Practice) is a standard for pressure vessel inspection within the petroleum industry. It provides guidelines for the inspection, repair, and maintenance of pressure vessels used in oil refineries and petrochemical plants. The API RP 572 inspection ensures that vessels meet the structural and safety requirements to prevent failures, leaks, and other hazards in high-pressure environments.

For prompt, reliable, and professional inspections, GOST Egypt for inspection services is your go-to partner. Whether you are searching for pressure vessel testing near me or want to discuss your specific requirements, we are just a call or email away.

Head Office

- Address: 122 Galal El Desouki Street, Wabor Elmyah, Bab Sharki, Royal Palace Tower, Alexandria, Egypt

- Email: info@gostegypt.com

- Phone: +2 03 4228 204 – 4228 234

- Mobile: +2 0106 668 4007

- Fax: +2 03 4228 234

Cairo Office

- Address: 8 El Sudan Street, El Dokki, Cairo, Egypt

- Email: cairo@gostegypt.com

- Phone: +2 02 3760 6450

- Mobile: +2 0109 002 6744

- Fax: +2 02 3760 6450